How to Choose a Reusable Ice Pack for Your Cooler

Reusable ice packs for coolers have become an essential solution across food storage, outdoor activities, and cold chain logistics. Whether you are packing lunch boxes for daily use or maintaining food safety during transport, selecting the right ice pack directly affects cooling duration, temperature stability, and overall efficiency.

This guide explains how to choose the right reusable ice pack for your cooler, based on material science, application scenarios, and cold chain best practices.

Understanding What a Reusable Ice Pack for Cooler Really Does

The Role of Reusable Ice Packs in Cold Chain Management

In cold chain systems, temperature control is critical to food safety and quality. According to the U.S. Food and Drug Administration (FDA), perishable food must be kept below 40°F (4°C) to prevent bacterial growth. Reusable ice packs serve as passive cooling agents that stabilize internal temperatures during storage and transit.

Unlike loose ice, reusable ice packs:

· Do not create meltwater contamination

· Maintain consistent cooling curves

· Are easier to standardize in cold chain operations

How Cooling Performance Is Determined

The cooling efficiency of a reusable ice pack for cooler depends on:

· Phase change temperature of the gel

· Heat exchange surface area

· Shell material thickness and thermal conductivity

The International Institute of Refrigeration (IIR) highlights that controlled phase change materials (PCMs) outperform traditional ice in predictable temperature maintenance, especially for food and pharmaceutical transport.

Choosing the Right Ice Pack Based on Application Scenarios

Ice Packs for Lunch Boxes and Daily Food Storage

For lunch boxes, compactness and safety are key. Ice packs for lunch boxes should:

· Be slim and lightweight

· Use non-toxic, food-grade gel

· Fit standard bento or insulated lunch containers

Centers for Disease Control and Prevention (CDC) recommends using gel-based ice packs instead of loose ice when packing perishable foods for work or school, as they reduce leakage and improve hygiene.

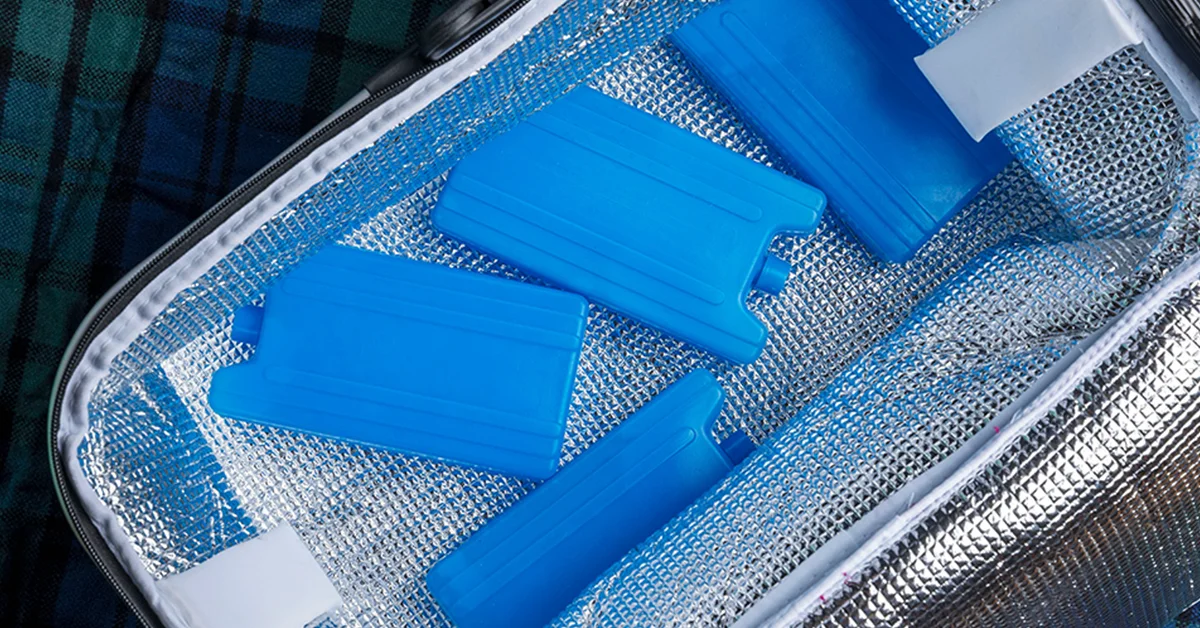

Ice Pack for Food Transport and Outdoor Coolers

When selecting an ice pack for food transport or large coolers:

· Prioritize longer cooling duration (8–24 hours)

· Choose thicker packs with higher gel volume

· Ensure durability for repeated freeze–thaw cycles

These features are especially important for camping, catering, seafood transport, and meal prep logistics.

Material and Construction: What Actually Matters

Gel Composition and Thermal Performance

High-quality reusable ice packs typically use polymer-based hydrogels or PCM-enhanced gels. These materials:

· Absorb and release heat slowly

· Maintain a stable cooling range

· Reduce temperature spikes inside coolers

The European Food Safety Authority (EFSA) notes that sealed polymer gels are safe for indirect food contact when properly encapsulated.

Outer Shell Durability and Safety

A reliable reusable ice pack for cooler should have:

· Leak-proof, heat-sealed seams

· Food-grade PE or nylon composite film

· Resistance to puncture and compression

Double-layer or reinforced edges significantly extend product lifespan in commercial cold chain use.

Comparison Table: How to Evaluate Reusable Ice Packs

|

Selection Factor |

Why It Matters |

Recommended Choice |

|

Cooling Duration |

Determines how long food stays safe |

8–24 hours |

|

Gel Type |

Affects heat absorption |

Polymer hydrogel or PCM |

|

Shell Material |

Prevents leaks |

Food-grade PE/PVC composite |

|

Size & Shape |

Fit for cooler/lunch box |

Flat or modular design |

|

Reusability |

Cost and sustainability |

500+ freeze cycles |

Quick Selection Form: Find the Right Ice Pack for Your Cooler

Please check all that apply:

· Used for lunch boxes

· Used for food transport

· Used in cold chain logistics

· Needs to last over 12 hours

· Requires food-grade certification

· OEM/ODM customization needed

If you selected more than three options, a customized reusable ice pack solution may be more suitable.

Sustainability and Cost Efficiency Considerations

Reusable ice packs reduce single-use plastic waste and long-term costs. The United Nations Environment Programme (UNEP) has emphasized reusable cold storage products as part of sustainable packaging strategies in food systems.

Compared with disposable ice or dry ice, reusable ice packs:

· Lower operational costs

· Reduce environmental impact

· Improve compliance in regulated cold chain environments

About INTCO Medical

INTCO Medical is a global manufacturer specializing in reusable cold and hot therapy products, including reusable ice packs for coolers, lunch boxes, and food cold chain applications. With vertically integrated production and OEM/ODM capabilities, INTCO Medical supports international brands and distributors seeking leading reusable ice pack manufacturers with scalable supply and compliance-driven manufacturing.

FAQ: Reusable Ice Pack for Cooler

Q1: How long does a reusable ice pack stay cold in a cooler?

A: Depending on gel type and cooler insulation, most reusable ice packs maintain cooling for 8–24 hours.

Q2: Are reusable ice packs safe for food contact?

A: Yes, when made with food-grade materials and sealed properly, they are safe for indirect food contact.

Q3: Can reusable ice packs replace ice in cold chain transport?

A: In many scenarios, yes. Reusable ice packs provide more consistent temperature control and cleaner handling.

Q4: How many times can a reusable ice pack be reused?

A: High-quality packs typically withstand 500 or more freeze–thaw cycles.