From Mass Production to Medical Standards: The Evolution of the Cold Pack Factory

Introduction

The cold pack factory has undergone a profound transformation—from simple industrial mass production facilities to highly regulated sites producing medical cold packs that meet stringent global standards. This evolution has been driven by market demand, technological innovation, quality system requirements, and the increasing application of cold therapy in healthcare and sports medicine. In this article, we analyze this trajectory, focusing on modern cold pack manufacturing, the rise of OEM cold packs, and the importance of becoming an ISO certified manufacturer.

Industrial Beginnings: The Rise of Cold Pack Manufacturing

Mass Production and Global Supply Chains

At its inception, the cold pack factory centered on cold pack manufacturing at scale to meet growing demand from general consumers and industrial markets. The core product—ice packs or gel cold packs—was primarily utilized for food transportation and basic cooling applications. According to industry directories, China remains a global epicenter for cold pack production, with major industrial clusters in Guangdong, Jiangsu, and Shanghai supporting large-scale output and export logistics. Manufacturers in these regions leverage automated filling lines and vertical supply chains to produce millions of units monthly with competitive turnaround times.

Expanded Applications: Sports and Everyday Uses

As global economies expanded and lifestyle sports gained popularity, demand for cold pack products grew beyond industrial use. Cold pack manufacturing adapted to include flexible gel packs, reusable cold therapy packs, and instant cold packs suitable for athletic injury treatment, first-aid kits, and consumer health products. These products, while initially developed for general use, laid groundwork for more specialized medical-grade iterations.

Transition to Healthcare: Medical cold packs

The Move Toward Clinical Use

With increased recognition of cold therapy’s benefits—such as reducing inflammation and managing acute pain—the healthcare sector sought more reliable products. Medical cold packs clearly differentiated themselves from consumer-grade alternatives through standardized temperature profiles, biocompatible materials, and robust safety controls. Studies show that controlled cooling from medical-grade products can significantly minimize risk compared to improvised ice therapy, reducing infection and tissue damage concerns in clinical environments.

Regulatory Requirements and Quality Management

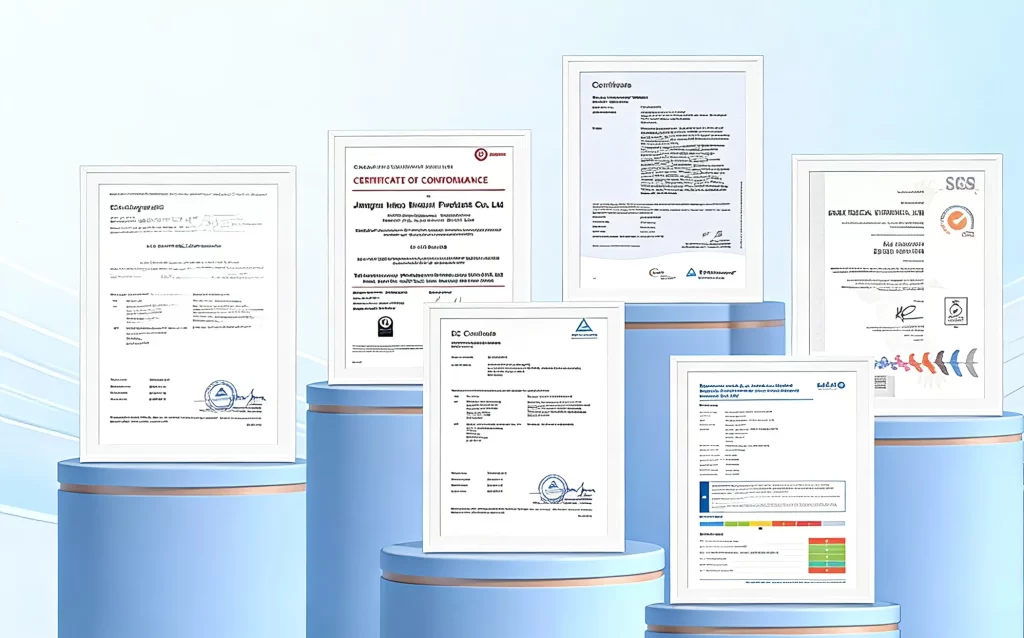

Producing cold packs for clinical applications requires adherence to medical device standards. ISO 13485, a globally recognized quality management standard specific to medical device manufacturing, defines requirements for production, design control, risk management, documentation, and supplier oversight. According to the International Organization for Standardization, ISO 13485 provides a quality management system framework that ensures consistent manufacturing processes tailored to medical device safety and regulatory compliance.

In practice, ISO certified manufacturers implement strict quality protocols covering raw material handling, process validation, in-process controls, and post-market surveillance. As noted by quality experts, such certification not only reduces product defects but also facilitates access to regulated markets, such as the European Union and North America, where compliance with global standards is mandatory for medical devices.

OEM cold packs: Customization for Healthcare OEMs

Today’s cold pack factory landscape has diversified to accommodate OEM cold packs—customized products designed and manufactured for specific brands, healthcare providers, and medical supply channels. OEM offerings include customizable sizes, gel properties, and packaging solutions tailored to distinct therapeutic uses (e.g., surgical recovery, chronic pain management, EMS kits).

OEM production requires not only manufacturing agility but also strong quality systems that align with both the OEM’s brand standards and regulatory expectations. This trend underscores the strategic role of contract manufacturers in the value chain, enabling medical device companies to scale without maintaining in-house production facilities.

Technological Innovations in Cold Pack Factory Operations

Automation and Efficient Production

Modern cold pack factories integrate automated filling systems, precision sealing technology, and real-time quality monitoring to achieve consistent product performance. This mechanization enhances reliability, reduces human error, and supports high-throughput manufacturing that meets both industrial and clinical demand.

Material Advancements

Advances in polymer gels and phase change materials (PCMs) have enabled extended cooling durations and tailored thermal profiles, making medical-grade cold packs safer and more effective. These innovations allow products to maintain therapeutic temperature ranges for longer periods, crucial for clinical outcomes in post-operative care or injury management.

Market Trends and Future Directions

Growth in Medical and Consumer Sectors

The global medical cold pack market continues robust growth, driven by healthcare infrastructure expansion, aging populations, and rising sports-related injuries. Market data projects steady expansion as healthcare systems increasingly adopt non-pharmaceutical modalities for pain and inflammation management.

Sustainability and Innovation

Manufacturers are also responding to sustainability pressures, innovating with recyclable materials, biodegradable packaging, and energy-efficient production methods. Future facility upgrades are expected to include greener technologies while maintaining compliance with critical medical standards.

INTCO Medical and the Modern Cold Pack Factory Model

As the industry continues to evolve, manufacturers like INTCO Medical represent the next generation of cold pack factories—bridging large-scale production with medical-grade standards.

By integrating automated mass production with ISO-certified quality systems, INTCO Medical supports:

· Medical cold packs for hospitals and clinics

· OEM cold packs for global healthcare brands

· Large-volume, compliant manufacturing for international markets

This combination positions INTCO Medical among discussions of the largest cold pack manufacturer and the largest cold packs factory serving both consumer and professional medical sectors.

Conclusion

The transformation of the cold pack factory from mass production to medical standard manufacturing reflects broader shifts in healthcare and industrial practices. Today’s leading facilities are defined by their ability to blend scale with quality—producing medical cold packs that meet strict regulatory criteria, support OEM partnerships, and maintain global market competitiveness. Organizations like INTCO Medical exemplify these advancements, leveraging ISO-certified processes and extensive OEM capabilities to serve diverse markets.

As the industry continues to grow, topics such as ISO certified manufacturer, the largest cold pack manufacturer, and the largest cold packs factory remain central to supplier evaluation, procurement strategies, and regulatory compliance.

FAQ — Cold Pack Factory & Medical Manufacturing

Q1: What defines a medical-grade cold pack factory?

A medical-grade cold pack factory operates under ISO 13485 or equivalent standards, uses biocompatible materials, and maintains full quality traceability.

Q2: Why is ISO certification important in cold pack manufacturing?

ISO certification, such as ISO 13485, ensures that a manufacturer adheres to internationally recognized quality and safety standards for medical products, enhancing regulatory compliance, product reliability, and global market access.

Q3: What is the difference between consumer and medical cold packs?

Medical cold packs require stricter material safety, temperature control, and quality documentation compared to consumer products.

Q4: Can OEM cold packs be customized for hospitals?

Yes. OEM cold packs can be customized in size, shape, labeling, and packaging to meet hospital or brand-specific requirements.