Global Market Trends Influencing the Future of the Cold Pack Manufacturer

The Expanding Global Demand for Cold Pack Manufacturers

The role of the cold pack manufacturer is evolving rapidly as global healthcare systems, rehabilitation centers, and home-care markets place greater emphasis on non-invasive pain management and injury recovery. Cold therapy products are no longer limited to basic first-aid use; they are now widely integrated into physical therapy products, post-surgical recovery protocols, and long-term rehabilitation programs.

According to the World Health Organization (WHO), musculoskeletal disorders are among the leading causes of disability worldwide, driving sustained demand for effective cold therapy solutions. This trend is reshaping how cold pack manufacturers innovate, scale, and serve global markets.

Key Market Trends Shaping the Cold Pack Manufacturing Industry

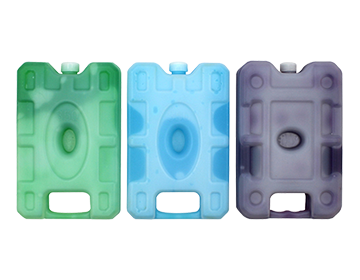

Growing Preference for Reusable Gel Packs

One of the most influential trends in the industry is the shift toward reusable gel packs. Healthcare providers and distributors increasingly favor reusable solutions due to cost efficiency, environmental considerations, and consistent therapeutic performance.

Reusable gel packs offer:

· Stable temperature retention

· Reduced medical waste

· Long-term value for institutions and patients

The American Physical Therapy Association (APTA) highlights cryotherapy as a standard modality in physical rehabilitation, reinforcing the need for durable and reliable reusable cold packs within clinical treatment plans.

Integration into Physical Therapy Products and Protocols

Cold packs are now deeply embedded in modern physical therapy products portfolios. From sports medicine to post-operative care, cold therapy supports inflammation control, pain reduction, and accelerated recovery.

The Mayo Clinic notes that cold therapy is widely recommended for acute injuries and post-treatment recovery, strengthening its role in standardized care pathways. For a cold pack manufacturer, this integration requires products that meet clinical expectations for safety, comfort, and repeat use.

OEM Gel Pack Manufacturing as a Strategic Growth Channel

Rising Demand for OEM Gel Pack Solutions

As global brands expand their medical and wellness product lines, OEM gel pack manufacturing has become a strategic priority. Distributors and private-label brands seek manufacturing partners that can provide scalable production while maintaining consistent quality across markets.

OEM-focused cold pack manufacturers typically support:

· Custom shapes and sizes

· Branded packaging and labeling

· Market-specific compliance requirements

This trend positions manufacturers as long-term partners rather than commodity suppliers.

Supporting Medical Supply Companies Serving Multiple Countries

For medical supply companies serving multiple countries, supply chain reliability and regulatory alignment are critical. A capable cold pack manufacturer must demonstrate the ability to support multinational distribution with stable production capacity and standardized quality systems.

This includes:

· Compliance with international medical regulations

· Multilingual packaging capabilities

· Consistent performance across diverse climates and markets

Such capabilities are increasingly essential for global procurement teams.

Innovation and Compliance in Cold Pack Manufacturing

Material Innovation and Product Performance

Material science continues to play a key role in cold pack development. Advanced gel formulations improve flexibility at low temperatures, enhance user comfort, and extend product lifespan.

According to Harvard Health Publishing, effective cold therapy depends on consistent temperature delivery without causing skin damage—placing material safety and performance at the forefront of manufacturing priorities.

Regulatory Expectations for Global Distribution

As cold packs are widely used in medical environments, manufacturers must align with the expectations of medical device manufacturers for global distribution. This includes structured quality management systems and clear documentation supporting product safety and intended use.

Global buyers increasingly evaluate cold pack manufacturers not only on price, but also on regulatory readiness and long-term compliance.

INTCO Medical and the Future of Cold Pack Manufacturing

As a globally recognized manufacturer of medical and rehabilitation products, INTCO Medical continues to play an important role in the cold therapy market. With established expertise in reusable gel packs, physical therapy products, and OEM gel pack manufacturing, INTCO Medical supports distributors, healthcare systems, and private-label brands worldwide.

Through scalable manufacturing capabilities, consistent quality systems, and experience serving international markets, INTCO Medical works closely with medical supply companies serving multiple countries and medical device manufacturers for global distribution. Its comprehensive product portfolio and global reach position INTCO Medical among the best ice pack manufacturer options for long-term partnerships in the evolving cold therapy industry.

FAQ – Cold Pack Manufacturer and Market Trends

Q1: Why are reusable gel packs becoming more popular in healthcare?

A: Reusable gel packs offer cost efficiency, environmental benefits, and consistent performance for repeated clinical and home use.

Q2: What role do cold packs play in physical therapy products?

A: Cold packs are widely used to reduce inflammation, manage pain, and support recovery in physical therapy and rehabilitation settings.

Q3: Why is OEM gel pack manufacturing important for global brands?

A: OEM manufacturing allows brands to customize products while leveraging established production, compliance, and supply chain expertise.