Freezer Blocks vs. Ice Packs: Which Is Better for Food and Medical Use?

When choosing a cold storage or cooling solution—whether for food delivery, medical transport, or personal therapeutic use—one often faces the choice between freezer blocks and ice packs. Each has strengths and weaknesses depending on the scenario. In this article, we’ll define both types, compare their performance (cooling, duration, safety, cost), explore ideal use cases in food and medical sectors, and give guidance on selection.

Definitions & Core Principles

What Exactly Are Freezer Blocks?

Freezer blocks are rigid or semi-rigid containers filled with water, gel, or other phase-change media, intended to be frozen and then used as a thermal reservoir. They are often shaped as flat slabs, bars, or molded blocks, and are reusable. Their design aims to provide a stable cold sink with minimal mess, especially in cooler boxes or insulated containers.

Some freezer blocks use gel inside to extend cold retention; others are simple water-filled units. According to an expert guide, high-quality freezer blocks can last 12 hours or more under good insulation and avoid the mess of melting ice.

What Are Ice Packs / Gel Packs?

“Ice pack” is a broad term. Typically, it refers to pouches or bags filled with water, refrigerant gel, or gel beads, which are frozen and then used to cool adjacent items. Some ice packs are reusable (gel packs), and some are instant chemical packs (activated by mixing chemicals).

Per the Wikipedia definition: reusable ice packs use water or non-toxic refrigerants and play the role of thermal mass, whereas instant cold packs use endothermic chemical reactions.

The gel packs usually remain pliable when frozen, enabling better contact with items or skin. They often use water combined with superabsorbent polymers like sodium polyacrylate, which helps hold the gel state and resist leakage.

The Thermodynamic Principle — Heat Absorption & Phase Change

The cooling power of a frozen medium comes from its latent heat of fusion (melting) plus sensible cooling (lowering from freezer temperature to melting point). When ice (solid water) melts, it absorbs a large amount of heat at a nearly constant temperature, which makes ice a strong cooling reservoir. Gel packs, depending on formulation, may have different thermal properties.

In practice, a pure ice block often provides a higher heat absorption capacity per unit weight, but gel packs offer tradeoffs in flexibility, shape conformity, and leak resistance.

Performance Comparison — Cooling Efficiency & Duration

Initial Cooling Rate

In direct comparisons (e.g., gel pack vs ice bag on human skin), ice bags often produce a faster initial drop in surface temperature. For example, a study applying a gel pack and ice bag to knees found that the ice bag achieved a more effective temperature drop during the first 20 minutes. Over longer repeated applications, the performance of both tends to converge.

Thus, for applications requiring rapid temperature reduction, pure ice (or blocks) may have an edge.

Duration of Cold Maintenance

Gel packs or freezer blocks with optimized phase-change gels often maintain lower temperatures for longer periods under insulation, especially once they approach equilibrium with the load. Many gel pack makers advertise 24–36 hours of effective performance under insulated conditions.

However, in less optimal insulation or ambient conditions, ice blocks may still outperform due to their high latent heat. The tradeoff depends heavily on insulation quality, ambient heat loads, and frequency of opening containers.

Uniform Contact, Shape, and Efficiency

Ice blocks are rigid and may leave air gaps around irregular shapes in a cooler or package. Gaps reduce thermal contact and allow warmer air intrusion. Gel packs or flexible freezer blocks that conform to the shape minimize air gaps and improve cooling efficiency.

Gel-based packs can wrap or lie flush against food or medical vials, distributing cold more uniformly.

Leakage, Mess, and Practical Handling

When ice melts, the resulting water can accumulate and cause leakage or drips, which needs draining. Freezer blocks and well-sealed gel packs avoid such a mess. They also reduce the risk of item contamination by liquid water.

In summary, freezer blocks and gel packs often offer cleaner, more user-friendly operation compared to loose ice.

Suitability for Food Use (Food Cold-Chain & Catering)

Food Safety & Cleanliness Considerations

In transporting perishable food, contamination is a major concern. Melting ice can collect and distribute bacteria or drip onto food surfaces. Freezer blocks and sealed gel packs mitigate that.

Also, gel packs designed for food transport are labeled food-grade, non-toxic, and free from harmful additives. In contrast, some older gel packs used ethylene glycol or other toxic substances, which led to recalls. One source warns that gel packs made with diethylene glycol or ethylene glycol are unsafe if ingested; hence, food-grade, non-toxic gels are strongly preferred.

Temperature Maintenance & “Danger Zone” Control

For food safety, keeping the temperature under ~5 °C (or perishable food regulatory limits) is critical. Cold reservoirs must buffer against ambient heat, particularly during transport. Freezer blocks with higher capacity and good insulation can hold food at a safe temperature longer.

In food shipping, gel packs are often used in “2–8 °C” cold chain boxes to maintain safe refrigeration without freezing the product itself. Gel packs with melting points above freezing are advantageous because they cool without freezing the product.

Use in Catering / Meal Delivery

In meal delivery or catering, lightweight freezer blocks or flexible gel packs are preferred because they do not crush or leak, and they maintain cleanliness in insulated delivery boxes. Their slim form allows them to be placed over or under food trays with minimal wasted space.

Suitability for Medical Use (Therapeutic & Transport)

Transporting Pharmaceuticals, Vaccines, Lab Specimens

In medical transport, maintaining a stable cold chain (e.g. 2-8 °C, −20 °C, or −80 °C) is critical. Freezer blocks with high thermal capacity are often used in medical shipping containers, cold boxes, or vaccine carriers. They buffer against ambient temperature swings and help keep payloads within required ranges.

One packaging guideline suggests using cold packs rather than dry ice when the product must not freeze. Gel packs can maintain the target temperature without dropping below freezing, protecting temperature-sensitive items.

Safety & Regulatory Compliance

Medical-grade freezer blocks and gel packs must comply with regulations, e.g. being non-toxic, biocompatible, and UN-certified for transport. They should be leak-proof and safe under pressure or vibration. The pore measures (size, packaging tolerance) matter in medical logistics.

Advantages, Tradeoffs & Best Use Scenarios

Summary of Strengths & Weaknesses

|

Feature |

Freezer Blocks / Rigid Blocks |

Gel / Flexible Ice Packs |

|

Cooling capacity per unit mass |

High (especially ice-based) |

Moderate (depends on gel formula) |

|

Initial cooling rate |

Strong |

Slightly slower in many cases |

|

Duration under good insulation |

Good |

Very good, may exceed blocks under optimal design |

|

Shape conformity / contact |

Poor |

Excellent |

|

Leakage / mess |

Minimal (if sealed) |

Minimal if quality sealed |

|

User comfort (medical use) |

Rigid, less conforming |

Flexible, safer for body contact |

|

Ease of stacking / storage |

Easier stacking of blocks |

More adaptable layouts |

|

Cost & reusability |

Durable, potentially lower cost per cycle |

Slightly higher cost but reusable many times |

|

Risk of toxic leakage |

Low (if water gel) |

Dependent on gel chemistry, must be food/medical grade |

Which to Choose When — Food Use Recommendations

· For long-duration transport (overnight or multi-day), freezer blocks or high-performance gel packs combined with strong insulation are preferred.

· For short-distance catering or meal delivery, flexible gel packs are more practical, space-saving, and cleaner.

· When transporting food that must not freeze (e.g. fresh produce, proteins), gel packs with melting point above 0 °C are safer than ice-based blocks or dry ice.

· In food service or catering boxes, avoid loose ice; blocks or sealed packs maintain sanitation and reduce cleanup.

Which to Choose When — Medical Use Recommendations

· For patient use (cold therapy), flexible gel packs outperform rigid blocks for comfort and safety.

· For medical shipments (vaccines, pharmaceuticals), freezer blocks with high thermal mass are excellent buffer elements in transport containers.

· For point-of-care or emergency use, instant cold packs (single-use ice packs) may be used, but they often have a shorter duration.

· Always ensure medical grade, purity, non-toxicity, and regulatory compliance when used in healthcare settings.

Practical Tips for Maximizing Performance

Insulation & Container Design

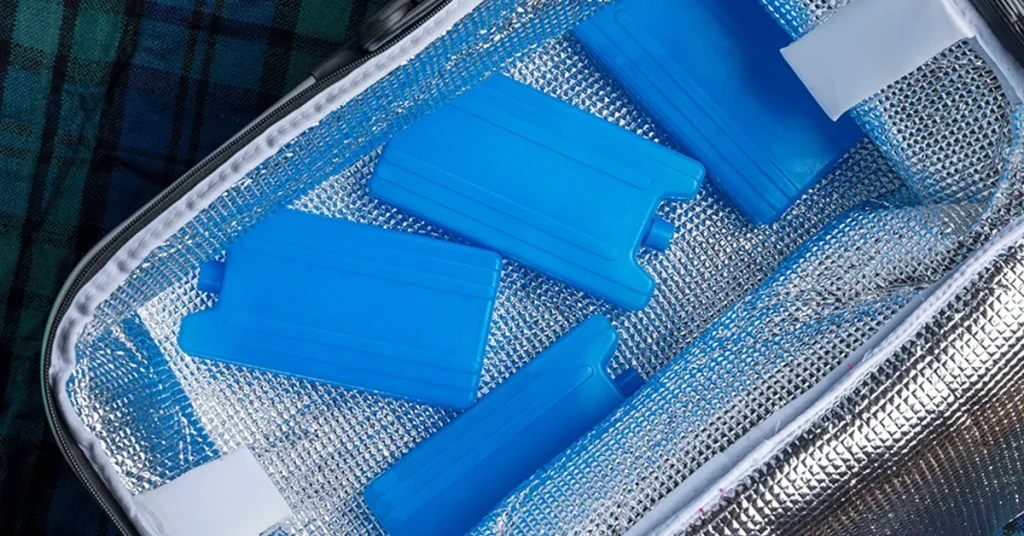

Even the best freezer block or ice pack will underperform without good insulation. Use high-quality insulated containers (foam, vacuum panels), limit air exchange, pre-chill the container, and place cold packs optimally (top & bottom).

Preconditioning & Freeze Protocols

Ensure blocks or packs are fully frozen before use. For larger blocks, allow sufficient time in a freezer with airflow so gel or water is fully solidified. Avoid partial freezing which weakens performance.

Load Balancing & Packing Strategy

Distribute cold sources evenly around the load. In a cooler, placing a cold source on top helps cool downward. In medical packaging, surround items with blocks or gel packs for uniform cooling.

Monitoring & Replacement Strategy

Use temperature loggers or indicators (ThermoLabels) to monitor payload temperature. Replace or refreeze blocks or packs if they lose performance. For reuse, inspect for cracks or leaks and discard damaged units.

Future Trends & Innovation

· Phase Change Materials (PCMs): Packs engineered with specific melting points tailored to food or pharmaceutical temperature windows.

· Smart Packs: Integrated sensors that monitor temperature and signal when a pack is nearing phase change.

· Hybrid Systems: Combining freezer blocks with gel packs to leverage fast cooling and long duration phases.

· Improved materials: More durable, puncture-resistant shells and safer, higher-heat absorption gels.

· Integration in logistics platforms: Prepackaged cold boxes designed with modular block slots for flexible load sizes.

Conclusion & INTCO Medical’s Role

In summary, freezer blocks and ice/gel packs each have their places depending on the application. For food transport, freezer blocks offer robust cooling capacity and are ideal for longer journeys, but flexible gel packs shine in catering, clean operation, and tight space usage. In medical contexts, gel packs dominate for patient comfort in therapeutic use, whereas blocks or high-capacity packs serve well in shipping and cold chain logistics.

When selecting, consider the required temperature range, duration, insulation quality, shape conformity, and safety (toxicity, leak risk).

As a trusted provider of cold storage and therapeutic products, INTCO Medical offers a full line of freezer blocks and gel pack solutions tailored for both food-safe and medical-grade use. Our products are designed for durability, safety, and performance in demanding real-world environments.

FAQ (Frequently Asked Questions)

Q1: Which holds cold longer, freezer block or gel pack?

It depends on insulation and formulation. In high-quality systems, gel packs can match or even exceed blocks in duration. But in simple setups, ice-based blocks may outperform.

Q2: Can ice packs be used for food and medical simultaneously?

Yes, but ensure they are food-grade and non-toxic. For medical use, ensure compliance with safety and regulatory standards.

Q3: Are gel pack gels toxic if leaked?

Most modern packs use non-toxic gels (e.g. water + sodium polyacrylate) safe for indirect food contact. However, packs with ethylene glycol or diethylene glycol are unsafe and have been recalled historically.

Q4: Can I use freezer blocks for cold therapy on people?

You can, but they may be rigid and uncomfortable. Gel packs are generally better for body contact. Always use a barrier cloth and limit duration.

Q5: How many freezer blocks / packs do I need for a shipment?

A rough rule in cold chain logistics is to use cold mass equivalent to ~30–50% of the payload weight for 24-48 h cooling, but this varies by insulation, ambient conditions, and packaging design.