Cold Chain Logistics 2025: Freezer Block Innovations for Medical Transport Introduction

Cold chain logistics is the backbone of modern healthcare, ensuring that vaccines, biologics, laboratory samples, and temperature-sensitive medicines arrive safely and effectively. Maintaining a stable temperature during transport is critical — even a slight deviation can cause product degradation or render a shipment unusable.

In 2025, the demand for more reliable, cost-effective, and reusable cooling solutions has led to renewed interest in gel-type freezer blocks. These simple yet powerful cooling tools are the unsung heroes of medical cold chains, bridging the gap between expensive active refrigeration and single-use ice packs.

This article explores how reusable freezer blocks are evolving, their advantages in medical transport, and how manufacturers are improving performance, sustainability, and efficiency for the years ahead.

The Importance of Freezer Blocks in Medical Logistics

Reliable Temperature Control

In the transportation of vaccines, diagnostic reagents, and plasma products, temperature stability is everything. Gel-based freezer blocks are pre-frozen at set temperatures (commonly –20 °C or –10 °C) and placed inside insulated boxes. Their high water-based gel content absorbs heat gradually, keeping the internal temperature within a safe range for 12–48 hours depending on configuration and ambient conditions.

According to the World Health Organization (WHO) Good Distribution Practices, cold chain packaging must maintain defined temperature ranges throughout the entire transport process. Freezer blocks, when correctly conditioned, provide a passive and compliant way to achieve this goal — particularly for regional and last-mile deliveries.

Use in Vaccine and Biological Sample Transport

Many hospitals, research centers, and blood banks rely on gel freezer blocks for daily transport needs. Unlike dry ice, which can be hazardous and regulated for air shipment, gel blocks are non-toxic, reusable, and safer for personnel handling. They can be used in insulated containers to maintain 2–8 °C, the standard range for most medical products.

|

Application Area |

Temperature Range |

Common Cooling Duration |

Typical Container Type |

|

Vaccine transport |

2–8 °C |

24–48 hours |

Insulated medical cooler |

|

Blood & plasma |

–10 °C to –20 °C |

12–36 hours |

Cold box with double-layer gel packs |

|

Diagnostic reagents |

0–5 °C |

24–72 hours |

Laboratory shipping box |

|

Hospital pharmacy supply |

2–8 °C |

12–24 hours |

Portable cooler with reusable blocks |

How Gel-Type Freezer Blocks Work

Composition and Structure

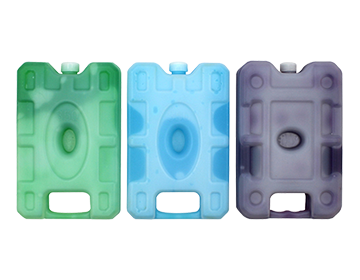

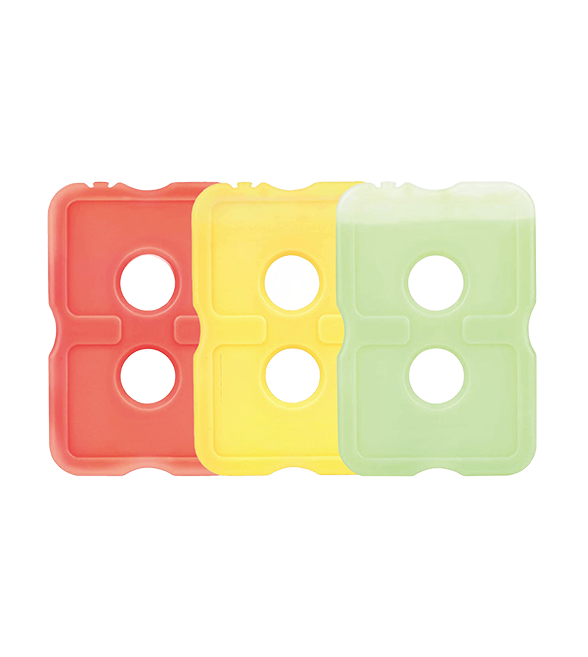

A typical medical freezer block is filled with polymer water-based gel or hydrogel compound, sealed inside a durable HDPE or PP shell. When frozen, the gel stores large amounts of latent heat, slowly absorbing warmth as it melts.

Unlike pure water ice, gel formulations have added thickening agents and stabilizers that extend cooling time and prevent leakage. Some designs feature ribbed or honeycomb surfaces to increase surface area and cooling efficiency.

Advantages over Traditional Ice

- Longer cooling duration: Gel maintains temperature longer than water ice because of its slow melting behavior.

- No condensation mess: Gel packs stay clean and do not produce excessive water after thawing.

- Reusable: Can be refrozen hundreds of times without performance loss.

- Safe and non-toxic: No dry ice or chemicals; environmentally safe for disposal.

- Customizable shapes and sizes: Designed to fit into cold boxes, vaccine carriers, or thermal crates.

Freezing and Usage Tips

For best performance, freezer blocks should be frozen for at least 12 hours before use, ensuring the entire gel content is solid. Positioning also matters: the blocks should be evenly distributed to prevent temperature gradients within the container.

Trends Shaping the Freezer Block Market in 2025

Focus on Reusability and Sustainability

As healthcare systems seek to reduce waste, reusable freezer blocks are becoming the standard choice. Many medical distributors now require multi-cycle durability of over 300 uses and recyclable plastic casings.

This shift aligns with global sustainability goals, reducing dependence on single-use ice packs and minimizing plastic waste in the healthcare supply chain.

Improved Durability and Leak-Proof Designs

2025 models emphasize stronger shell construction and double-sealed edges to prevent leaks after repeated freeze-thaw cycles. Some manufacturers use ultrasonic sealing or double-wall molding to ensure consistent quality for long-term use in hospital logistics.

Temperature-Specific Gel Formulations

Different gels are now tailored to meet distinct medical transport needs — for example:

- –5 °C gel blocks for refrigerated vaccines;

- –20 °C gel blocks for frozen plasma;

- Phase-stable gels that stay semi-solid longer to prevent thermal shock to contents.

This product segmentation helps healthcare providers choose the optimal cooling element for their temperature-sensitive cargo.

Compact and Modular Storage

Newer freezer block designs are stackable, flat, and lightweight, making pre-freezing and storage more efficient. Modular block sets can be arranged flexibly in containers, allowing precise thermal control without excessive bulk.

Market Applications and Real-World Cases

Hospital and Clinical Use

Hospitals increasingly rely on freezer blocks to deliver temperature-sensitive drugs between departments, wards, and regional clinics. Their portability and reusability make them ideal for routine transfers that don’t justify active refrigeration systems.

Pharmaceutical Distribution

Pharmaceutical wholesalers use large cold boxes with 6–10 reusable gel blocks for inter-city delivery. The predictable performance and regulatory compliance make them an economical alternative to powered cooling containers for short and mid-range routes.

Laboratory and Diagnostic Logistics

Clinical laboratories and diagnostic centers use gel blocks to maintain sample integrity during courier transport. As molecular diagnostics and genetic testing expand, the demand for controlled-temperature transport continues to rise.

Veterinary and Life Science Applications

Freezer blocks also play a role in the cold chain for veterinary vaccines, pet bioproducts, and life science research materials. Their clean, non-corrosive nature makes them a preferred solution for these specialized sectors.

The Future of Freezer Blocks in Cold Chain Logistics

A Move Toward Global Standardization

The next few years are likely to see greater standardization in freezer block performance testing — including freeze time, cooling capacity, and reusability cycles. This will help align suppliers and ensure consistent quality across international medical supply chains.

Integration with Smart Packaging (Optional Layer)

While still simple in design, freezer blocks may soon include QR codes or indicators to help trace usage history, batch numbers, and freezing status — ensuring better accountability in regulated environments.

The Role of Manufacturers

Global healthcare suppliers increasingly rely on OEM/ODM manufacturers who can provide consistent quality, customization, and regulatory documentation. Partnerships with experienced producers allow brands to focus on logistics service while outsourcing the cooling component manufacturing.

INTCO Medical: A Reliable Manufacturing Partner for Cold Chain Cooling Solutions

INTCO Medical is a global medical manufacturer specializing in cold and hot therapy products, gel packs, and reusable freezer blocks for medical transport. With advanced manufacturing bases in China and international logistics capabilities, INTCO offers OEM and ODM services for global brands in healthcare, pharmaceuticals, and biotechnology.

· Durable, leak-proof HDPE shells;

· Eco-friendly polymer gel filling;

· Custom temperature ranges (–5 °C / –10 °C / –20 °C);

· Multi-cycle reusability for cost-effective transport;

· Strict quality control and international certification.

Whether for vaccine carriers, laboratory shipments, or hospital cold boxes, INTCO Medical provides dependable cooling components that help ensure the integrity of temperature-sensitive products worldwide.

Conclusion

Freezer blocks may look simple, but in the complex world of medical cold chain logistics, they provide a reliable, reusable, and environmentally friendly solution for temperature control. As 2025 brings new challenges in vaccine distribution, diagnostic logistics, and healthcare sustainability, gel-based freezer blocks are proving indispensable.

Their durability, ease of use, and cost-effectiveness make them a cornerstone of modern cold chain systems — especially when manufactured with precision and quality assurance.

With years of experience in thermal healthcare products and global OEM/ODM service, INTCO Medical stands ready to support healthcare and logistics companies with professional-grade freezer block solutions for reliable medical transport.